Problem and Solution

Bacteria, such as MRSA, survive on surfaces for months – viruses are able to remain active for weeks.

Thousands of people are infected and die due to (nosocomial) infections every year. The economic damage and suffering caused by such unnecessary infections is enormous. This could be significantly reduced by regular use of Biotech3D disinfection, e.g. in the patient's room or in the nursing areas.

3D Disinfection by Biotech3D Ultrasonic Applications

For decades, rooms and surfaces were solely disinfected through two-dimensional methods as e.g. through well known disinfection wipes.

Not all surfaces can be properly reached through conventional methods, not even from trained cleaning staff. Moreover, despite existing hygiene plans, unwelcome or hard-to-reach places are often insufficiently disinfected. The chemicals used are usually aggressive, but disinfection is only volatile.

Rewrite your Hygiene Plans!

This disinfective fog, which is produced in or outside the contaminated room, penetrates into all corners and cracks of the premises and eliminates germs such as resistant MRSA bacteria, E.Coli, dangerous noroviruses or flu viruses and also counteracts various fungi and yeasts, as well as bad organic odours.

Depending on the application, after at least 45 minutes of fogging, the rooms – well ventilated – can be used again as usual. Due to the chosen cationic mechanism and application of ion bonds, depot effect on surfaces and walls is achieved, this completing 3D disinfection.

These new technical possibilities allow existing hygiene plans to be revised. Even in phases of pandemics, the depot effect can create a decisive time advantage in the fight against pathogens.

In the above example of the wagon in public transport, a new standard is set in combination with well-known wiping technology with our 3D disinfection.

Typical contact surfaces are disinfected (on a daily base) through wipes, while the 3D depot effect wards off airborne pathogens on non-contact surfaces. Thus, the hygiene standard raise to a completely new level with hardly any more personnel costs.

Old school vs. 3D disinfection

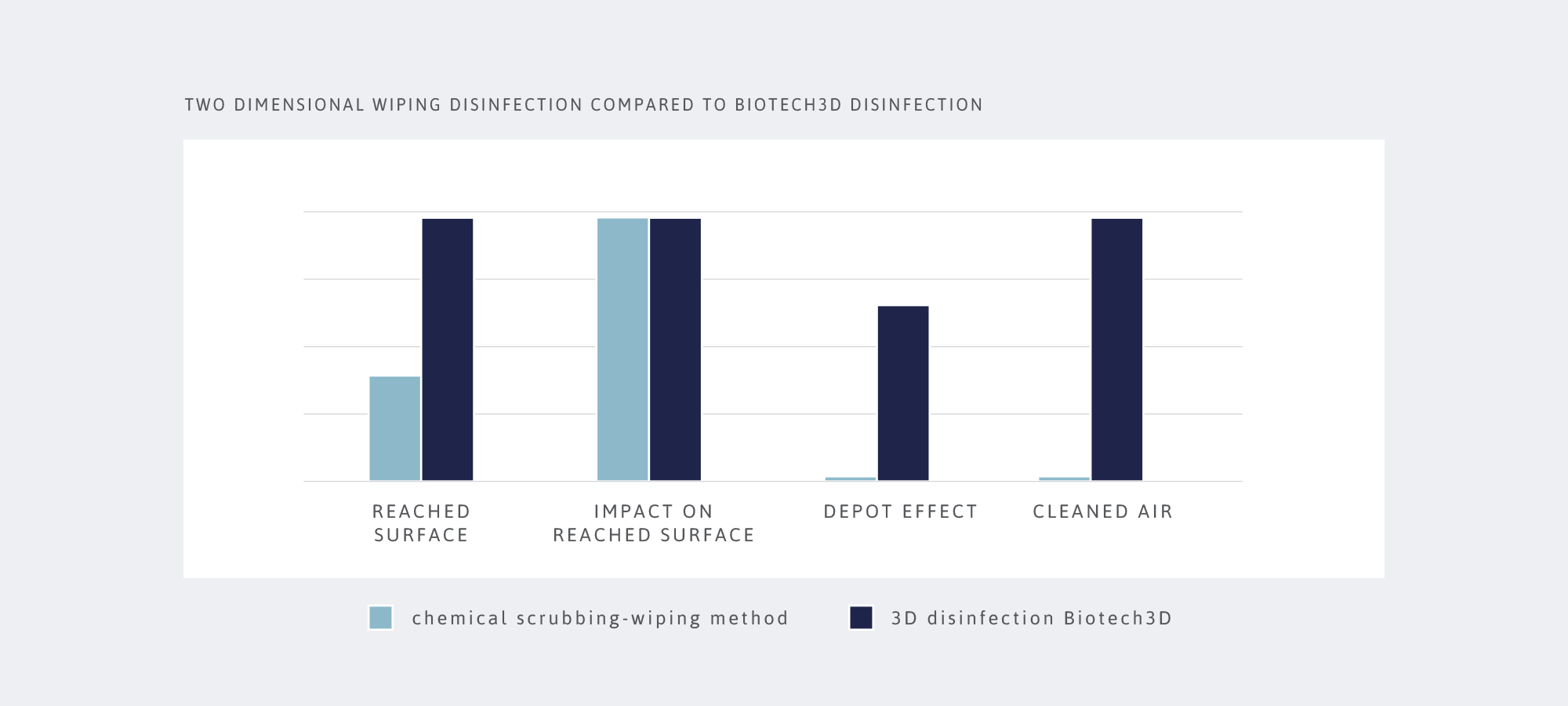

Two dimensional wiping disinfection has systemic deficiencies in effectiveness and is also subject to human error. The following graphic illustrates the advantages of three-dimensional thinking in the Biotech3D process. The aim is to use both methods in combination to ensure the best possible quality in efficiency.

Biotech3D produces Aerosols, not Droplets !

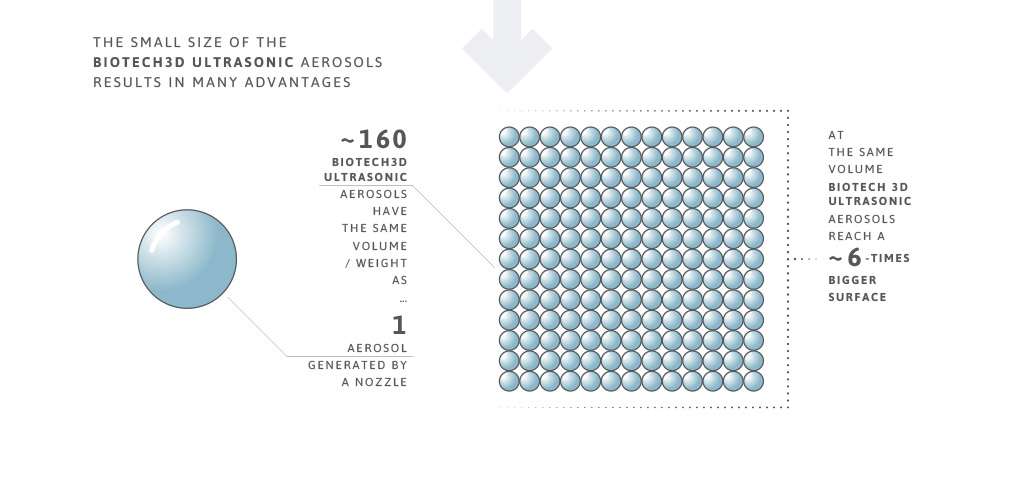

The ideal measure for the average aerosol is based on the size of the bacterial pathogens. This is significantly smaller than an aerosol or droplet from the cold misting method by means of a nozzle.

Even conventional ultrasonic membrane technologies do not achieve the high Biotech3D ideals without additional technical separation of generated aerosols. For example, one particle generated by a special german fogging nozzle equals approx. 160 aerosols produced by Biotech3D. Many of the various benefits derive from this fact.

Performance - Efficiency

- Wide broadband effect against viruses, bacteria, fungi and organic odours.

- Reduced particle diameters (<10 microns) create more active surfaces.

- Application for complex as well as small rooms.

Increased Profitability

- Less biocide consumption. Approximately 160 times more fog particles compared to special fogging nozzles.

- Quiet and fast usage.

- High-quality, almost maintenance-free product.

- Reduced preparational work time (no unnecessary room sealing due to e.g. cables, air-tubes).

- Improved security conditions for disinfectors by remote access to the device D2400 (via tablet).

Design

- Intelligent design increases user comfort and mobility.

- Advanced technology allows disinfection from outside of the room.

- Modern, user-friendly and multilingual application.

- Increased safety at work - no stumbling blocks due to compressed air-tubes.

- Chimney attachment allows individual transport of the generated aerosols.